Rulmeca new products range for unit handling has been extensively renewed, allowing the Group to move ahead.

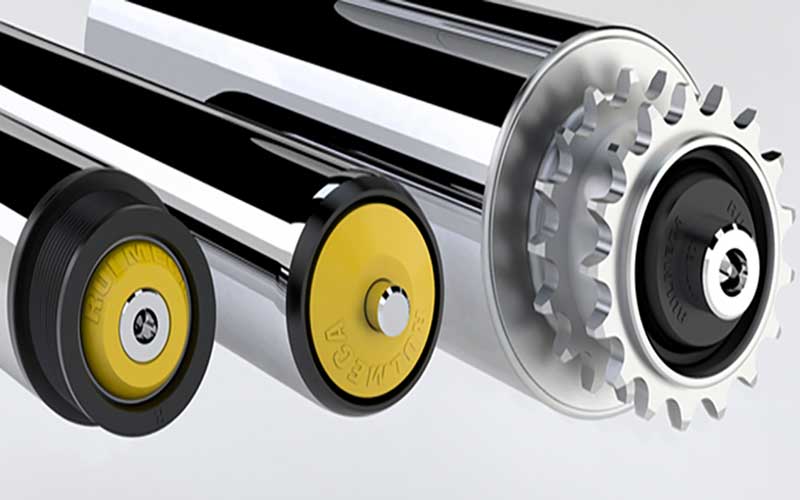

The range of components for unit handling, all made by Rulmeca, comprises of different rollers and components to make:

- Gravity conveyors

- Chain driven conveyors, with accumulation or with zero accumulation

- Belt driven conveyors, with accumulation or with zero accumulation

- Gravity curves, chain driven curves, belt driven curves

These rollers are all products of high quality and reliability for unit handling in all fields of applications.

The Rulmeca Flow Storage team is at your complete disposal to analyse the volume and rotation of your unit loads, the turnover of your goods, to collect all the special requests and recommend the most suited system for your needs.

We adjust the flow storage solution to your situation by examining the space, the times, the production and the volumes.

We work closely with you to propose the right solution to improve the efficiencies, enabling the correct return on investment, with the possibility of a full turn-key supply too.

All the components of Rulmeca Flow Storage solutions are tested in our laboratory and answer to high quality standards.

Rulmeca Flow Storage solutions are designed and supplied according to the anti-seismic norms in force on the area of the installation.

In a belt conveyor one may identify two types of troughing sets: the upper carrying sets, that have the function to support the loaded sections of the belt and to move the material; and the lower sets that support the unloaded belt on its return section.

The upper troughing sets may basically be in two arrangements: flat, with a single horizontal roller generally supported by two fixed brackets from the conveyor structure; troughed, generally with 3 rollers supported within a frame which is itself fixed to the conveyor structure.

There may be then, in the loaded sections, impact troughing sets that have rollers with rubber rings or suspended “garland” sets.